2021 has been another strange year for most, with much uncertainty surrounding the pandemic and having to adapt to new ways of working to ensure compliance with the ever-changing government guidelines.

For us, 2021 has marked some major milestones in our business and despite the challenging backdrop we’ve continued to grow, securing new business both nationally and internationally and firmly cementing our reputation as one of the UK’s leading defence engineering specialists.

One of the biggest changes for us this year has been relocating to a much larger premises to enable us to meet the increased demand for our products. We’ve gone from a 6,000 square foot unit on Port Talbot Waterfront Enterprise Zone, to signing a ten-year lease for a 20,000 square foot unit on the same enterprise zone. The additional space will be critical for our ambitious growth plans in the coming years and we’re already feeling at home in our new unit. It was a real moment when we had our branding completed on the outside of the building, marking it as ours.

Speaking of branding, we’ve also given our brand identity a complete refresh this year. Since we started the business in 2016, we haven’t just grown as a team, we’ve established our core values and have built a reputation based on these values. It’s our precision, quality and design capabilities that set us apart from competitors and we wanted our branding to reinforce this.

We took part in a really interesting exercise to help us identify exactly what we stand for as a business, we’ve refreshed our logos, re-invested in our social media marketing and will be launching a brand-new website which encapsulates our new identity in the new year!

Something that’s featured highly on the agenda in 2021 is climate change, with events such as the COP26 summit taking place as well as so many horrific climate related disasters including major floods in Germany and China, fires ripping through Canada, California and Greece and rain, rather than snow, falling for the first time at the summit of a rapidly melting Greenland.

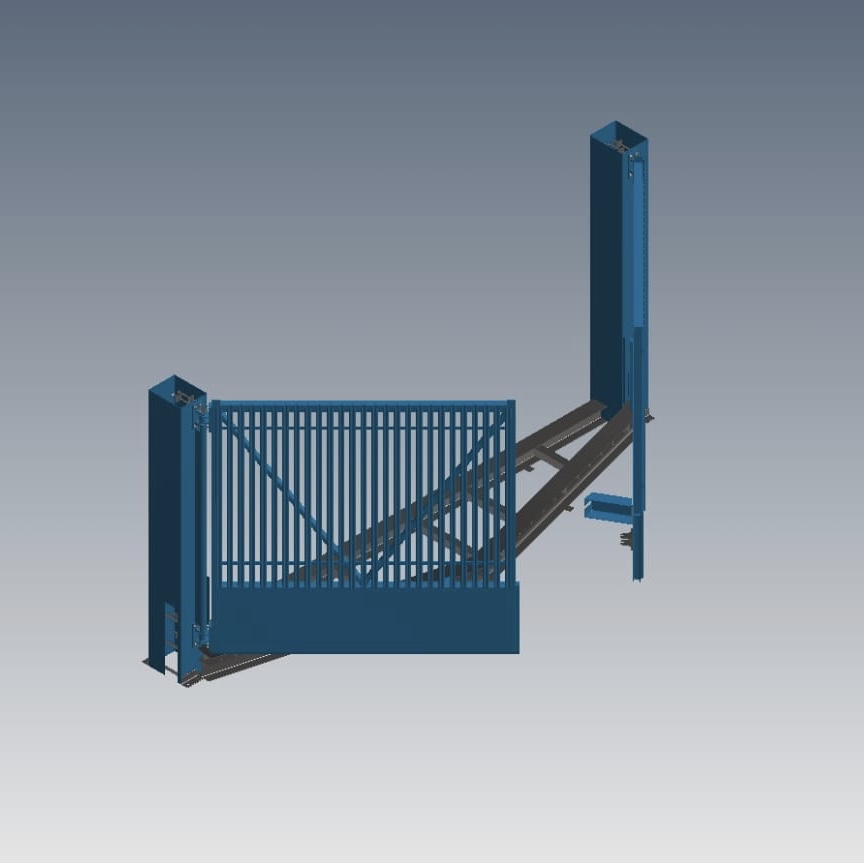

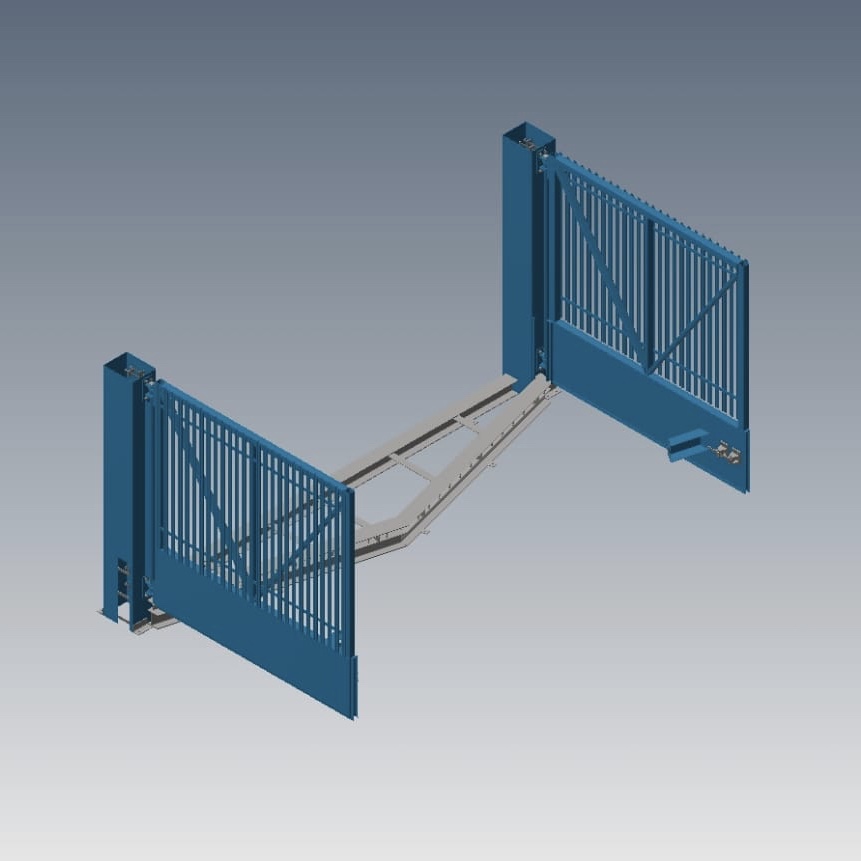

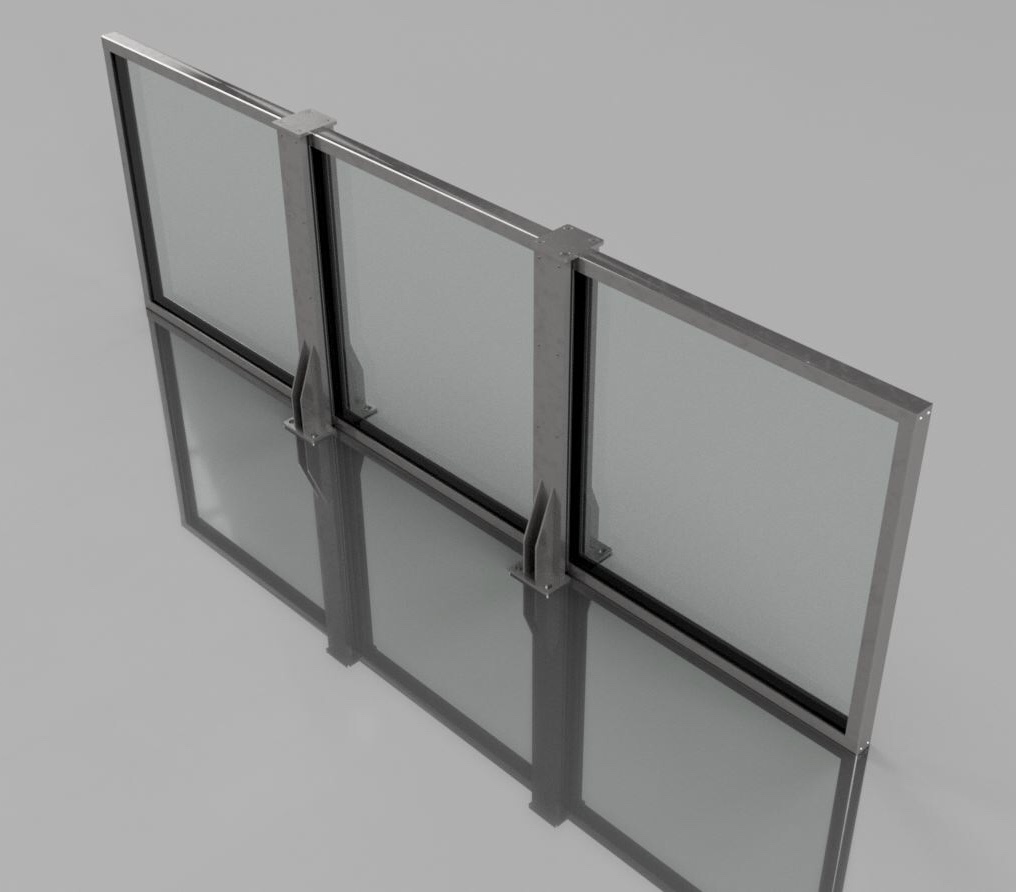

The stakes are higher than ever before, and the demand for flood and blast defences is soaring. We’ve grown our customer base in South East Asia and have contracts in the US and Middle East in the pipeline. Gaining international recognition for our products which are specially engineered with the unique requirements of each of our customers in mind, is the best accolade we can achieve. It’s testament to the superior quality of our design, manufacturing and installation processes and we’re incredibly proud of our team.

As we look to the new year, our focus is simple: to increase production capacity and deliver on demand without compromising on quality. We’ll be looking to grow our team and have our eyes on the global market as we look to export Welsh products and skills.

We’ll be sharing our journey as well as our products, case studies and our latest news across our social channels so make sure you’re following us on Twitter, LinkedIn, Facebook and Instagram.

From everyone at MM Engineering, we hope you have an enjoyable Christmas break and we look forward to working together in the New Year.